Solution 1 lipstick

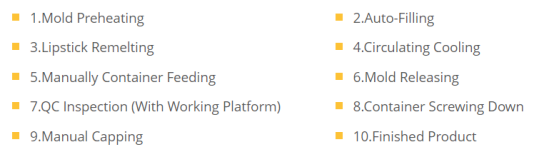

If you need to produce your own brand lipstick, you may follow the lipstick working process as below:

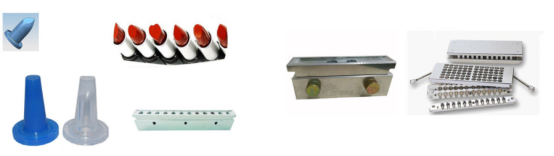

Lipstick is a necessary demand for cosmetic users. If you want to make lipstick , the first you need is to choose the shape of lipstick. We have many different sharp of lipstick mould to meet your requirement. And we can also product the mould which matches with your lipstick samples. How to choose the lipstick, we provide half-silicone, fully-silicone and metal mould for you. You can also choose the cavities of the mold.

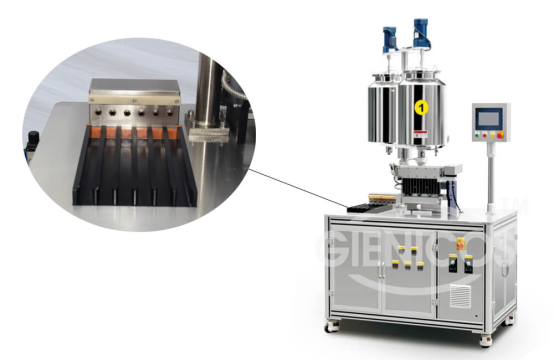

The main body of GIENI lipstick machine is made of stainless steel, and the material contact part is made of 316L, which is easy to clean and anti-corrosion. The preheating system depended on the mold you choose. Preheating system use Swiss imports hot gun or uniform heating board. The hot air blowing tubes is made of stainless steel, and there is a cover prevent operator form scald. This kind of preheating system usually use for silicone molds and we have design another preheating solution for metal molds.

Project Name: 2017 Thailand Lipstick Production Line

Project product: Lipstick Filling Machine with Preheating and Remelting, Cooling Tunnel, Working Platform, Lipstick Mould Releasing Machine. This lipstick filling line use half-silicone molds and have complete function.

Project Name: 2018 USA Lipstick Filling Line

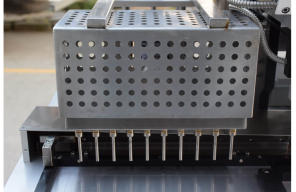

Project product: 12 Nozzles Lipstick Filling Machine + Metal Molds + Lipstick Demolding and Screwing Down Machine

The preheating system for this machine is special designed for metal lipstick molds. Fill 12 pcs/time, filling volume set on the touch screen. The machine is small, precise and easy operate.

Project Name: 2019 Thailand Lipstick Production Line

Project product: Lipstick Production Line with Preheating and Remelting, Cooling Tunnel, Working Platform, Lipstick Mould Releasing Machine and Container Screwing Machine. This lipstick filling line is used for half-silicone molds and have complete function.

Project Name: 2020 Vietnam Lipstick Filling

Project product: 10 Nozzles Lipstick Filling Machine + Silicone Molds + Cooling Tunnel + Vacuum Releasing Machine

This is an economic lipstick filling line suits for small scale production. The preheating system for this machine is special designed for silicone rubber. Fill 10 pcs/time, filling volume set on the touch screen. Dual temp. control to ensure filling result. The machine is small, presice and easy operate.

Project Name: 2021 France Lipstick Molding Machine

Project product: Automatic Lipstick molding Machine with Preheating and Remelting, Cooling, vacuum Releasing Machine and Container Screwing Machine. It gives 1300pcs/hour production capacity, suits for full silicone rubber.

Want to Know More, Contact Us!